Team 8404 Presents Our 2020-2021 Robot

FRC3PO

FRC3PO’s Success this Season

Winning the Industrial Design Award Internationally

Our team competed internationally in this season's challenges and won the Industrial Design Award sponsored by General Motors! This award celebrates our team's implementation of crucial industrial design principles—whether in our advanced computer vision & autonomous driving software, innovative robot design, and high performance—to create a robot with a perfect balance between form and function. As the only rookie team (first-time competitor) out of hundreds of NorCal teams to win a robot design award, we are extremely proud of all the hard work that we have put in this season to achieve such a prestigious award sought after by veteran super-teams around the world.

Receiving the Rookie All-Star Award at the Blue League CADathon

At our first ever CADathon, we were pleased to be rewarded with the Rookie All-Star Award at Blue League’s CADathon! All members of our team gained exposure CADing different subsystems of a robot and critical robot design knowledge during this offseason event.

Learn More About FRC3PO

Watch the Journey

Autonomous Capabilities

One of the highlights of FRC3PO is the autonomous code and sensors that allow it to interact with its environment and really feel alive. The robot has a high-res ultra-wide camera that allows it to grasp the entire view of the playfield as well as the power cells and other elements found on it. Using a co-processor, a raspberry pi, running a convolutional neural network, the robot is able to process the camera feed and identify game elements on the field in less than a second with near 100% accuracy. With the field map created, we chart a path, and the robot then makes use of the drivetrain encoder and IMU sensor data to calculate and keep track of its position on the field. With proportional-integral-derivative controllers and the Ramsete algorithm, we coordinate drivetrain motor outputs, enabling it to reliably follow our generated paths to arrive at its destination.

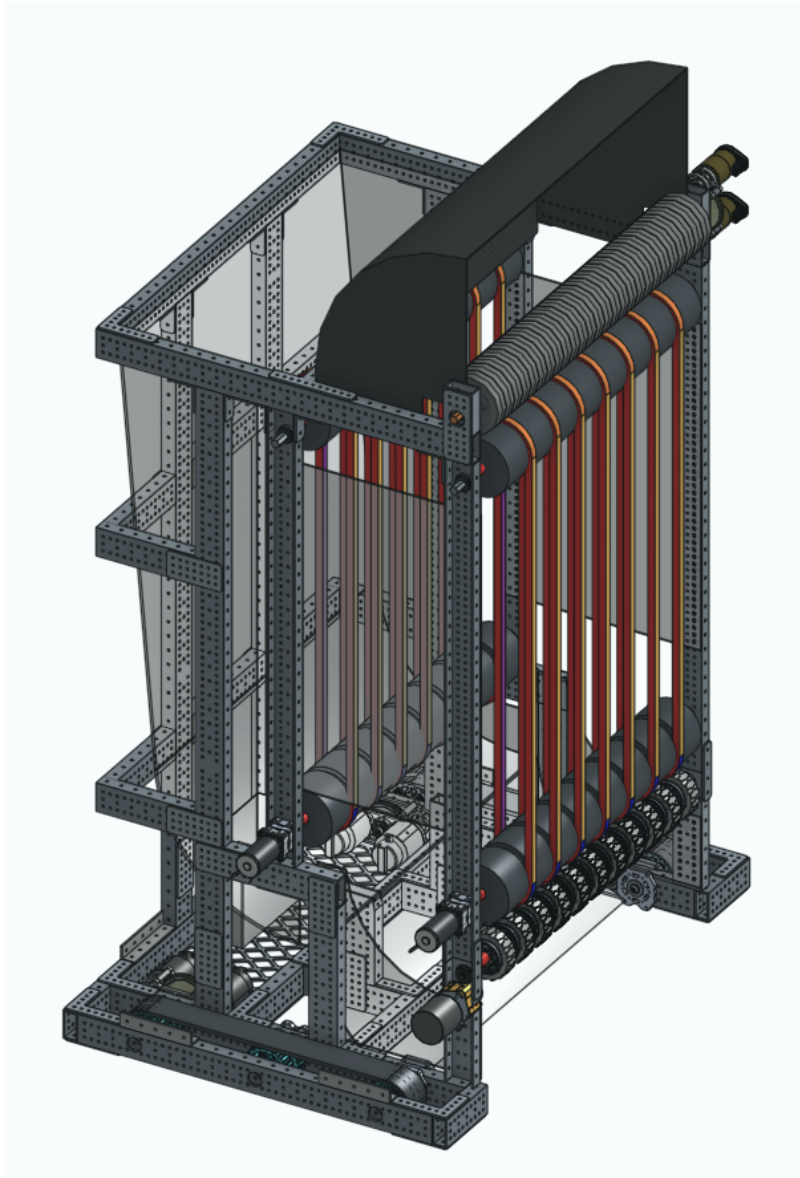

FRC3PO Arm Assembly

In this season's INFINITE RECHARGE at Home, we saw that, unlike other game challenges, these game objectives prioritized an efficient and easily maneuverable drivetrain with a streamlined intake and outtake system. Thus, our team combined 3 major components of our robot—the ball intake, outtake, and hopper—into an all-in-one, compact subsystem. By innovating beyond traditional methods of having individual subsystems, we saved time and skills that allowed us to better our team's software prowess and movement capabilities crucial to successfully achieving game objectives. Some of the specifics of our 3-in-1 robot arm that allowed it to be so successful were the springs that dramatically reduced the load on our motor to raise the arm up and down, the PVC pipes and churros that enclosed our hopper and allowed balls to seamlessly move throughout our hopper, the belt guard that protected our timing belt from ball interference in the hopper, and our hard stop mechanism that flips down automatically during tele-op and autonomous routines to angle our outtake arm perfectly with the low goal port.

FRC3PO Drivetrain

FRC3PO has a 6-wheel dropped center drivetrain in order to optimize smooth turning while maintaining a large construction footprint to have a sturdy base for the superstructure on top. Additionally, it utilizes 6” pneumatic wheels for driving smoothly on a broad range of terrains. The drivetrain is powered by 4 Falcon 500 motors coupled with a 10.71 gear ratio allowing the robot to rapidly traverse the playfield while also having sufficient torque to engage with other robots.